October 2010: Product Spotlight

Words: Dan Kamys

??Product Spotlight

Mason contractors are very aware of the added expense and the never-ending battle of working in cold temperatures while constructing masonry projects. Throughout the history of masonry construction, one of the single-largest costs and inefficiencies of working in the winter or any cold weather condition is generating a steady supply of warm water for mixing mortar and grout. The reality is that heating sand and water by way of propane gas and culvert pipe or direct flame on a barrel is a waste of money and time, not to mention that it introduces safety concerns. Considering all of the recent innovations impacting masonry products, practices and equipment, the need for a system that eliminates this jobsite challenge exists, especially a solution that increases the efficiency and productivity of a masonry crew.

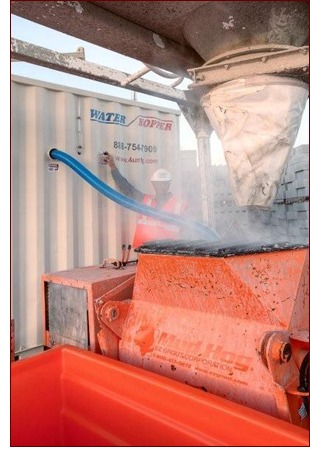

4U Manufacturing, a Wyoming-based company, researched this cold weather predicament and developed Water Hopper, a portable automatic water system that will place a pre-determined or variable amount of water into one or more mixers simultaneously. Operating with an innovative and energy-efficient technology, the Water Hopper is a labor-saving device that will heat and dispense water on the jobsite. The unit ensures that the preferred amount of water at the optimal temperature to meet code requirements is introduced for every batch.

Depending on the contractor’s needs and jobsite space, the unit is available in the larger capacity Extreme Water Hopper and the smaller Job Box Model. The Extreme model is an eight X 10-foot, standalone, insulated unit that optimizes fuel efficiency, provides protection from the elements, and is easily transported on site or from job to job. It has two metered storage tanks and can dispense from both sides of the shell, working simultaneously to fill two mixing stations, one on each side. Also available is a scaled-down version called the Job Box Model that is a smaller, more portable unit placed next to the mixer. With the flip of a switch, the Job Box produces hot water instantly.

Regardless of whether a contractor uses a silo system or small bags, mixing on site has never been as consistent and efficient as it is with the Extreme Water Hopper. The unit runs off AC or DC power, while using either propane or natural gas to generate heat and, ultimately, supplies mixing water with temperatures ranging from 98??F to 140??F. This allows the laborers to safely control the water-heating process and results in the desired temperature of mortar and grout as stated in Building Code Requirements for Masonry Structures (ACI 530/ASCE 5/TMS 402). With the simple pull of a lever, a predetermined amount of heated water is dispensed directly into the mixer.

Regardless of whether a contractor uses a silo system or small bags, mixing on site has never been as consistent and efficient as it is with the Extreme Water Hopper. The unit runs off AC or DC power, while using either propane or natural gas to generate heat and, ultimately, supplies mixing water with temperatures ranging from 98??F to 140??F. This allows the laborers to safely control the water-heating process and results in the desired temperature of mortar and grout as stated in Building Code Requirements for Masonry Structures (ACI 530/ASCE 5/TMS 402). With the simple pull of a lever, a predetermined amount of heated water is dispensed directly into the mixer.

With an output rate of up to 40 gallons every five minutes, the Extreme Water Hopper can provide all the hot water needed from a small to a very large project. Furthermore, while one batch of mortar or grout is mixing, warm water is automatically replenishing the Water Hopper’s metered tank, providing continuous material batch cycle times that can be set between three to six minutes. When utilizing the Water Hopper, batches of mortar and grout will always be the temperature desired by the contractor. With that said, jobsite inspectors can relax, knowing the temperature of the product going into the wall is always within tolerance for optimal performance.

As a problem solver with an extensive background in masonry equipment, the originator of the Water Hopper, Mike Capps of 4U Manufacturing, engineered the system while focusing on contractor benefits. Through research and development, talking with numerous mason contractors, and visiting jobsites to witness the different approaches used by mason tenders to heat water, Capps identified significant inefficiencies that hindered production and increased costs. It was clear that the Water Hopper system was needed to help contractors reduce those costs and increase production.

In cold weather climates mason tenders or laborers typically are required to be on site early, sometimes up to an hour ahead of the crew to heat water and prepare the first batch of mortar for the masons. The Extreme Water Hopper enables the mason tender to charge the first batch of mortar in the morning within five minutes of punching in and is ready to dispense heated water into the mixer for the second batch before the first mortar tub is loaded.

For more information about the Water Hopper, call 888-754-7909 or visit www.4Umfg.com.

Return to Table of Contents